Photo courtesy Suzy Lamont Photography

Story by Judy Wearing

In July’s heat wave, my laptop fried. More precisely, the semi-conductors in the power supply unit in the motherboard degraded. This was not, as I once supposed, due to the manufacturer’s “time bomb design” forcing me to buy a new computer. This was due to a limitation in the power supply technology, one of several limitations of great concern to engineers in the integrated circuit (IC, aka microchip) field who strive to make them smaller, more reliable, longer-lasting, less expensive, and more efficient.

Yan-Fei Liu, an engineering professor at Queen’s University, sits at his computer 14 hours a day, most days, contemplating this and related problems. He’s an expert at power conversion – how to take the 120 volts that come from the wall and channel/convert it to the voltage required by the components in our electronics. His 19 patents to date are evidence that he’s good at it.

Liu has recently joined forces with the Sumida Corporation, a Japanese company that specializes in one of the components of ICs – inductors. In basic terms, an inductor is “wire wound around a magnetic core.” It stores energy, coming in as one voltage when the circuit switch is on, and releases it at another, constant voltage. All electronic components rely on inductors to function. An inductor in our cell phones, for example, takes the 3.7 or so volts from the battery and sends it to the CPU at a steady 0.8 volts. To date, inductors have been a bottleneck in IC improvement, but working together, Liu and Sumida have redesigned the power supply unit.

Before the next decade, you and I will have access to electronics with power-efficient ICs, with longer battery life and less heat. Less heat is particularly important for server rooms, which store massive amounts of cell phone and internet data, and get very hot indeed, requiring air conditioning and regular replacement of motherboards. IC improvements are good for the environment, as well as consumers.

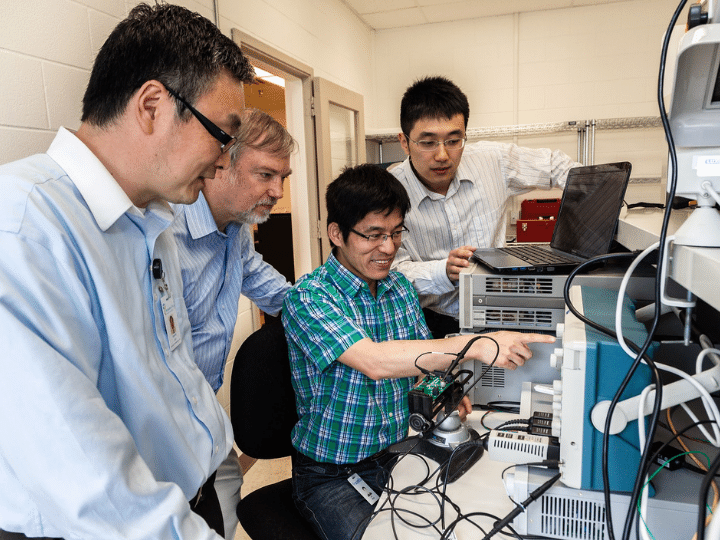

I met Liu and Doug Malcolm, senior VP of global research and development for Sumida, at their new offices in Innovation Park in Kingston. A friendly, energetic Liu drew circuit diagrams for me on a whiteboard, and gave me a tour of his lab – a room as big as my kitchen, equipped with a microscope to build tiny circuits and shelves lined with green and yellow buckets reminiscent of kindergarten, with labels like “MPS components and EVMS.”

Sumida’s presence in Kingston is the happy result of coincidence – both Liu and Malcolm worked at Nortel in the 90s. Without Malcolm, and his interest in Liu’s work, Sumida’s R&D would be elsewhere – along with the high paying jobs the burgeoning company will bring. When Malcolm told company headquarters he wanted to set up an R&D centre here, “they had no idea where Kingston was, they barely knew about Canada.”

Over a cup of coffee, Malcolm’s down-to-earth demeanor did not detract from his passion about technology in Canada. “A lot of what is going on in technology nowadays is overseas and we’ve lost touch, we’re losing touch … that’s not a good way to be as an advanced country. We need to keep our technology development here. Canadians don’t know how to manufacture electronic components anymore ... if we really want to grow we have to allow people from other countries to come in who have these special skills to help us regain this technical edge.”

“Why do we need a technical edge?” I asked.

“To improve our quality of life, to motivate our kids, to protect our future.”

“And our motherboards,” I add.

For more information about Sumida Technologies, please visit: www.sumida.com