Story by Ian Coutts.

September 28, 2016

Put together two inductors and you get a transformer; put two old friends together at Innovation Park and you get something equally transformative.

Doug Malcolm and Yan-Fei Liu first met working at Nortel in Ottawa back in 1994. Yan-Fei was a freshly minted PhD in electrical engineering from Queen’s; Malcolm was, as Yan-Fei puts it, “my boss’s peer” in Nortel’s power group. It was a big group, but tightly knit, and the men got to know each other quite well.

After Nortel disbanded the power group in the late 1990s, the two men went their separate ways – Liu back to Kingston, to take up a position at Queen’s in the Department of Electrical and Computer Engineering, Malcolm ultimately to Sumida, the Japanese manufacturer of inductors and other coil-based technologies.

Purely by chance, they met again in 2011, at the Applied Power Electronics Conference in Dallas. Malcolm learned that Liu was giving a paper on digital control. “I went to it,” he laughs, “and I didn’t understand a word of it.” Afterwards Malcolm, who was now senior VP of global research and development at Sumida, and Liu went to lunch to catch up and talked about their respective challenges. When they sit down to recount the story now, it is interesting to see how the two interact, each picking up the story from the other, finishing sentences or complementing the other’s thoughts.

Liu had a problem with inductors, the key element that enables the charger in your phone or your computer to take a flow of electricity and reduce its voltage, from 120 volts to 12 in the case of your computer’s power supply, for example, or from 3.7 in your cell phone battery down to 0.8. (This is a simplification. As Liu says, “You have more power supplies than you know. Even in a laptop there might be twenty.”)

“I told Malcolm it was a problem because the inductors are too big, but all the other components of the power supply are so small,” says Liu.

Creating a smaller power supply meant, says Liu, dealing with a contradiction. “Your cell phone charger now is much, much smaller than the one that came with your first or second cell phone,” he says. “We want everything smaller.” You can shrink an inductor by making it higher frequency, but says Liu,” “this creates a problem of power loss.” It also creates tremendous heat, which can affect the operations of the computer. It is for this reason that large groups of servers are kept in special air-conditioned rooms.

Thinking about this challenge, Doug and Liu came up with a novel solution. Don’t try to make the inductor smaller. Make it slightly larger – and then bury all the other components inside it. The end result would be a power supply that isn’t as big as before, but doesn’t suffer from the drawbacks of high-frequency inductors. The larger unit also gives a better “heat performance,” as Liu terms it, with the other components shielded by the inductor, which now acts as a heat sink.

Malcom knew they had a great idea. Would Liu help him realize it? Together, they approached Malcolm’s boss in Chicago and got the go-ahead to launch a Sumida R&D project – a rarity in North America.

Because Liu taught at Queen’s, Kingston seemed to be the logical place to locate their new endeavour. After many years away, Malcolm was ready to return to Canada. The company, a subsidiary of Sumida, formally got off the ground in January 2013.

The choice to locate at Innovation Park was surprisingly simple: “We started driving around looking for a storefront,” says Malcolm. “It was a snowy day. Out the window, I could see Innovation Park, and the minute I saw it, I liked it.”

“It may all seem quite informal,” says Steven Liss, Queen’s Vice-Principal (Research), “but business sometimes works that way. The important thing is to provide a framework where these informal relationships and lucky connections can grow into something lasting.”

They were able to set up shop right away, and later, Rick Boswell, the Assistant Director at Innovation Park and their “landlord,” was able to help them apply for a Natural Sciences and Engineering Research Council of Canada (NSERC) grant to cover the cost of a student to work in their lab. In August 2014, they also received a lucrative Collaborative Research and Development grant from NSERC, intended to underwrite mutually beneficial cooperative projects between university researchers and their private sector partners that benefit Canada economically.

For Sumida, the benefits of this product are twofold: they are answering a market need for smaller power sources, but they are not just selling a single component for a power source, worth Professor Liu estimates “maybe 20 cents.” What they are offering is a complete assembled unit, a far more lucrative business.

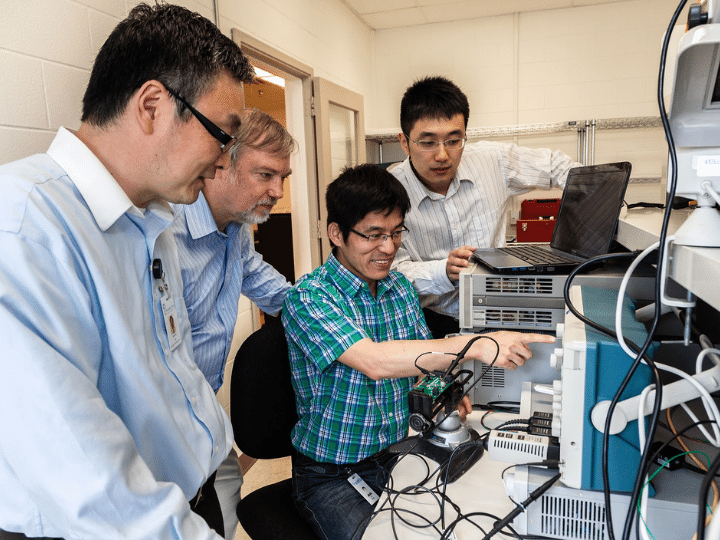

Malcolm and Liu have been granted a patent for their innovation, and they have five or six more pending. They are working to expand what they term their power supply in inductor model to work with different voltages and currents. Commercial interest in their idea is strong, and they have recently hired a marketing director to help them sell their product. All told, they have eight employees, six in Kingston at Innovation Park and two in Ottawa.

Three of them are Queen’s grads. “It is easier to recruit someone who is already here,” says Malcolm. The company currently also has a Queen’s PhD working in its lab, and Sumida recently hired another student on a year-long coop program. Post-Docs and graduate students from Queen’s who have put in time at Sumida at Innovation Park have gone on to jobs in Boston and Toronto. As Sumida grows at Innovation Park, says Malcolm, they will likely hire more. “As long as we’re here, we’ll have a connection with Queen’s.”

“Power, which is what we do, is a very practical area for students,” says Liu. “Creating the product is only 20 percent of what’s needed. They also learn about sourcing and environmental concerns, and so much beyond power technology. You never learn those things in school.”

It was an informal relationship that brought Sumida to Innovation Park, and Malcolm thinks this is something the university should pursue more of. “If they want to grow more businesses like this in Kingston, if they want to bring businesses like this back to Kingston, go out and look at your alumni. See who’s a president or a vice-president of an international company and say to them, ‘Hey, how about setting up a business in Kingston?’ That’s how we got together. That’s how a lot of companies are formed.”