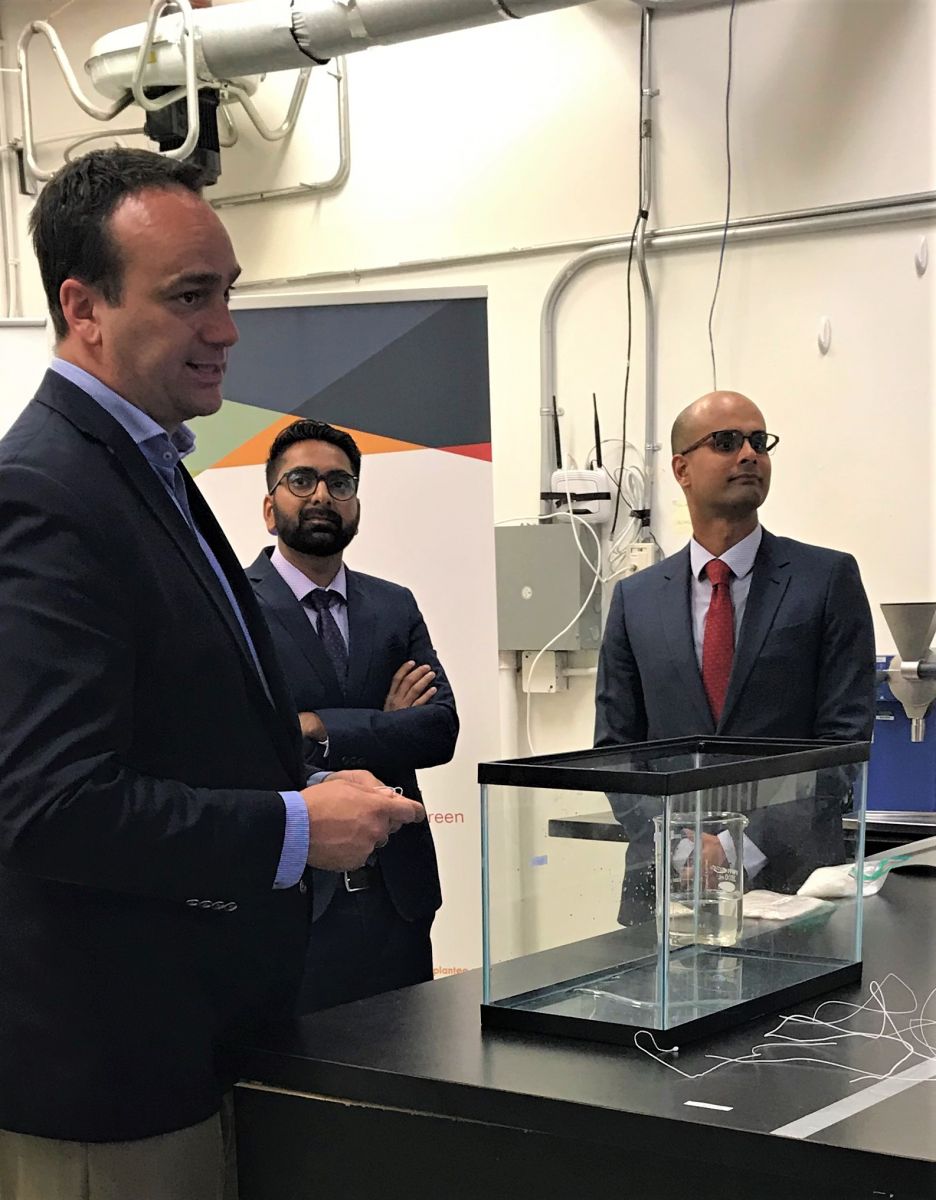

and Praphulla Tiwary (right) show

their product to Member of Parliament

for Kingston and the Islands, Mark Gerretsen.

Many technology startups set out to solve an identified problem in the market. This can start as a journey to find the right niche market that their product or technology fits into or they carve out a new space in the landscape. A new program developed by the federal government aims to support Canadian innovators and entrepreneurs by providing funds to solve pressing problems. The goal of the project is to facilitate the early development of a technology while allowing for testing and validation of the prototype and assisting in the pathway to commercialization.

The Innovation Solutions Canada (ISC) program identifies areas where the government is looking for novel solutions such as innovation platforms to streamline processes, improving recycling technologies or even open calls for interesting new developments.

Three Queen’s-connected companies have recently been selected to participate in the program: Spectra Plasmonics, Plantee Bioplastics, and Jeosal Materials Research Corp.

When Spectra Plasmonics saw the Health Canada-funded opportunity to develop point of care diagnostics to combat antimicrobial resistance, they decided to apply. In this project, Health Canada was looking for “novel, easy to use and cost-effective rapid point-of-care diagnostic and detection tool(s) that identifies and characterizes antibiotic resistant bacteria and/or distinguishes between viral and bacterial infections to address the rise of antimicrobial resistant infections.”

Spectra’s flagship product is a patent-pending technology that acts as an accessory to the user-friendly Raman Spectrometer, a device used for chemical identification. Spectra’s product increases the signal of chemicals scanned by these devices by approximately one million times, thus enabling trace detection capability decreasing the need for time consuming and more complex laboratory testing. The technology is based on research developed in the Department of Chemical Engineering by Professors Carlos Escobedo and Aris Docoslis and two PhD students, Hannah Dies and Josh Raveendran.

As a result of their application to the ISC, Spectra received $114,250 for a six-month Phase 1 grant project. The goal of a Phase 1 project from the ISC is to develop the proof of concept for the proposed solution. Spectra’s project began in July 2020 and wrapped up in December 2020.

“We advanced the technology from technology readiness level (TRL) 1 to above TRL3 for this particular use case (pathogen detection) and have a validation report now proving our potential for products in new markets,” says Malcolm Eade, one of the company co-founders, about the lessons learned through the funding project. “This funding gave us the opportunity to attract new talent and bring more technical resources in-house. While hiring experienced personnel and acquiring new capabilities is seemingly expensive up front, if invested wisely, it pays off and can open you up to new opportunities.”

Plantee Bioplastics heard about the program from Dr. Marianna Kontopoulou, Associate Dean (Academic) in Smith Engineering and Professor in the Department of Chemical Engineering. Founded by Queen’s chemical engineering alumnus Dr. Praphulla Tiwary and Queen’s chemistry alumnus Dr. Prashant Agrawal, this company has developed a novel fishing line that is strong and durable and remains stable in dry storage but biodegrades when exposed to water long-term thereby helping to keep waterways safe and clean for people and animals.

Plantee Biolastics applied to the Plastics Challenge: Sustainable Fishing and Aquaculture Gear, funded by the Department of Fisheries and Oceans. The goal of this project aims to find “economically and technically viable innovations in fishing and aquaculture gear or gear-related technologies to reduce or eliminate ghost fishing and aquatic plastic pollution caused by Canadian fisheries and aquaculture industries.”

Plantee has received funding to complete two phases of their project. Following the completion of a Phase 1 project, where the company received $138,000 to develop its proof of concept, Plantee received $475,000 in funding for Phase 2.

“A big success factor for Phase 1 was collaboration,” says Prashant Agrawal. “Working as a Chemist with Praphulla, a Chemical Engineer, we spent countless hours coming up with innovative ideas and carrying out experiments in the lab to prove that our proposed solution was viable. Having access to Dr. Kontopoulou’s lab at Queen’s proved to be quite useful for the Phase 1 completion.”

In the second phase, companies are provided with funding to develop a prototype. Plantee’s Phase 2 project is expected to wrap up in May 2022.

“We got a significant amount of help from Queen’s QPI team as they helped tailor our Phase 2 application and helped to train us on how to write an appealing project proposal. In addition to this, having completed all the suggested milestones for Phase 1 proved to be monumental in our Phase 2 success,” adds Prashant.

Jeosal Materials Research Corp, the third Queen’s-connected company to be successful with a project bid and who also credits their knowledge of the ISC program to Dr. Marianna Kontopoulou, addressed the Plastics Challenge: Recycling of Glass Fiber-Reinforced Plastic.

Led by Transport Canada, this particular challenge sought “novel, economically viable, and ecologically sustainable solutions for recycling or reusing glass fiber-reinforced plastic in a manner that is energy efficient and recovers as much material as possible (diverting from landfill).”

Jeosal Materials Research Corp was awarded $118,625 for Phase 1, which began in April 2019 and concluded September 2019. For the prototype development of Phase 2, Jeosal Materials was awarded $765,500. The project began last year in April 2020 and is scheduled to be completed by March 2022.

Thus far through their projects, Jeosal Materials Research Corp has successfully recycled and reused glass fibre reinforced plastic (GFRP) from three different sources – including GFRP panel from an end-of-life marine vessel – via a novel, patent-pending recycling process. All targets and outcomes for this project were completed on budget, on schedule and within scope, as defined by the ISC challenge.

With the completion of Spectra Plasmonics’ Phase 1 project and the continuation of the Phase 2 projects for Jeosal Materials Research Corp and Plantee Bioplastics, Queen’s continues to provide support to each of these companies, two of which participated in Queen’s inaugural Growth Accelerator program, two of which are members of the Queen’s Startup Runway, and all of which receive ongoing mentorship and support from Queen’s as well as other contributors to Kingston’s innovation ecosystem.