Plastics are ubiquitous in society as their versatility and robustness make them well-suited for preserving water and food security, shelter and clothing, transportation, health care, computing/communications, and the built environment. While these affordances – what society can accomplish with plastics - play an essential role in society, the growing impact of plastics, from microplastic dispersion in the environment to environmental costs from hydrocarbon-based production, necessitate prompt and effective action. Vulnerable populations bear much of the negative impact. Collectively, we need to realize plastics affordances with minimal environmental and societal impact.

End-Producer Responsibility legislation is growing in North America and Europe. Regulatory license to produce and use plastics is changing rapidly, creating a compelling imperative for plastics producers/users to move to sustainable use. Canada’s $35 billion plastic manufacturing industry supports 90,000 jobs but only 9% of plastic is recycled and 29,000 tonnes/year leaks into the environment[4,5].

Canada needs plastics circular economies that eliminate waste by design, reduce environmental impact and human health risks, with net economic benefits contributing to growth through higher productivity and job creation. The circular economy requires coordination between government (regulation, science investment), industry (plastic producers, users), waste management (companies, municipalities), and the public (consumer choice, education). Use-inspired university research, together with effective research translation to societal impact through industry uptake, venture formation, communication, policy uptake and public acceptance, are critical to meeting this challenge.

In order to meet this challenge, and catalyze the impact of undergraduate and graduate students and post-doctoral fellows in industry and society more broadly, we are providing training in the industrial application of technologies for monitoring plastics and converting plastics to useful compounds is required, complemented by training to identify opportunities for impact, develop and implement solutions, gather resources, and build social acceptance, in PLASTICS CREATE (PLastic Affordances through Science and Technology and Innovation for Circular Systems).

Areas of Research

Bioprocess and Analytical Technology

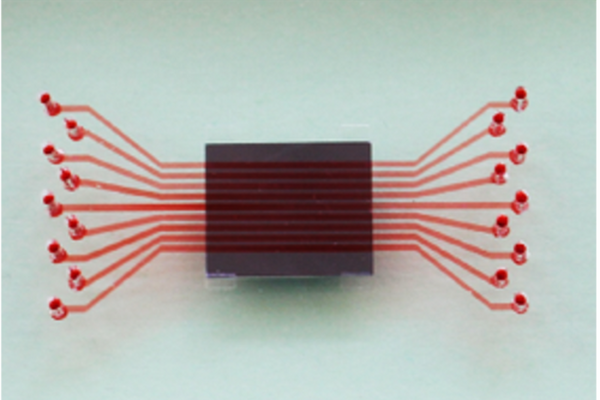

The goal of this research is to develop advanced screening platforms to characterize and monitor bioprocesses, focusing specifically on:

- improving throughput and speed

- non-destructive measurement

- expanding scope of applicability

- measurement sensitivity

Advances in these technologies will be used to optimize reaction conditions for plastic depolymerization, provide real-time monitoring in degradation processes, track microplastic generation during depolymerization, and for application to plastic mixtures.

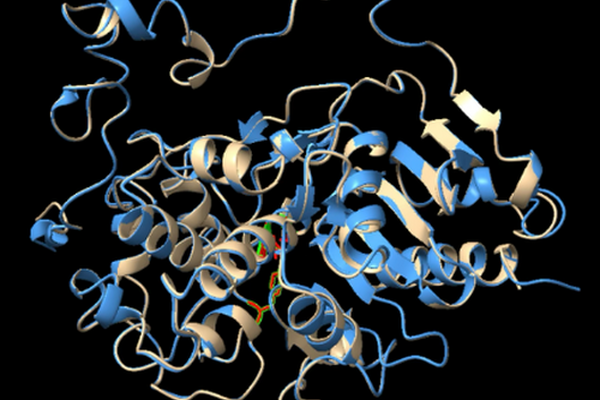

Depolymerization and Conversion Technology

Our industrial partners have identified a need to vaporize mixed resins and contaminated plastics (e.g., food debris, adhesive labels/laminates). Bio-based recycling is a potential solution as it can selectively degrade material with lower risk of hazardous waste production. While it is showing promise for polyethylene terephthalate (PET), these techniques are not yet effective for polyolefins (e.g., PE and PP, found in food packaging, bottles, drinking straws), which contain chemical bonds not readily broken down by enzymes.

The research in this area will focus on:

- discovery of new polyolefin bio-degradation biocatalysts (microbes, enzymes)

- development of hybrid processes to bio-degrade chemically treated plastic waste, using chemical oxidation to make plastics "digestible" for enzymes and microbes

- optimizing operating conditions to enhance degradation speed and selectivity

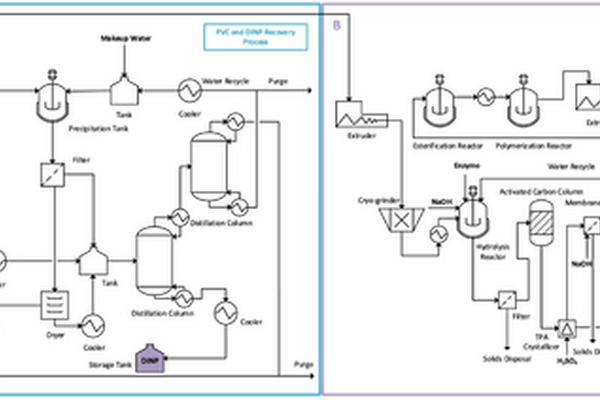

Integrated Process/Value Chain Design

Appropriate plastic degradation technology decisions depend on process placement relative to value chains, e.g., PET enzymatic degradation to ethylene glycol and terephthalic acid for re-polymerization), or degradation / conversion to other value-added chemicals. This research area will focus on:

- supporting integrated process / value chain design by formulating comprehensive mathematical mass flow models with Life Cycle Analysis (LCA) and Techno-Economic Analysis metrics with alternative pathways for derived chemicals

- developing static and consequential LCA will be developed to identify promising process/value chain subsets

- formulating and solving optimal technology choice problems as MI(N)LP models

These approaches will be linked to economic flow modelling.

Design for Circularity

Design for Circularity requires understanding the “jobs to be done” for consumers (e.g., retail food purchase in packaging) and businesses (e.g., wholesale food distribution from distant growers), central to building business models, while understanding societal relationship to plastics (attitudes/use). Our industrial partners emphasize the need for systems thinking

for designing circularity. Systems perspectives help identify innovation ecosystem relationships playing

pivotal roles in solution adoption. This research area will focus on:

- developing conceptual systems models (e.g., manufacturing/distribution/consumption/flow components) for socio-physical system representation

- using mathematical modeling (agent- and event-based / physical system models) to capture decision-making (agency) amongst consumers, business leaders, and policy planners, and interplay between human agency and material flow.

Science to Innovation and Impact

This goal of this research is to catalyze the translation of research science to commercial and societal impact, by informing policy decisions at all levels of government, and guiding strategic decisions by agents in science translation pathways (universities, industry, government). The research area will focus on:

- studying the role of pre-formation intangible assets (research excellence, patents, international networks) in science commercialization

- understanding the role of Open Science approaches in accelerating translation of research results at a pre-competitive stage, particularly in contexts where the goal is disruptive change

- investigating the importance of boundary spanners as venture founders, translational scientists and industry champions, and the potential role of dual-affiliated students (university/industry)

- developing graphical and mathematical representations for university-anchored innovation ecosystems to support design and assessment of policy and program decisions

Contextual Engineering, Equity, Diversity, Inclusivity and Indigeneity

Equity, Diversity, Inclusivity and Indigeneity play central roles as lenses for understanding the role and impact of plastics in societies around the world, reflected in place-based practices, and the impact of plastics environmental pollution on populations, and in particular, vulnerable populations that are disproportionately exposed. Contextual engineering: "creative application of science, mathematical models, societal understanding, and place-based knowledge to address a physical need that serves the user of the innovation, while recognizing the influence of stakeholder motivations, capabilities and values", provides an important approach for developing meaningful and impactful solutions.

This research area will focus on:

- expanding contextual engineering approaches to rural, remote, urban and organizational settings

- developing methodologies contextualizing the relationship between plastic materials and populations identifying propensity for user adoption of practices and materials

Qualitative/ethnographic and contextual approaches will incorporate diverse

perspectives through interview and observation study design, ensuring that models of behaviours and

impacts related to plastics are properly representative.