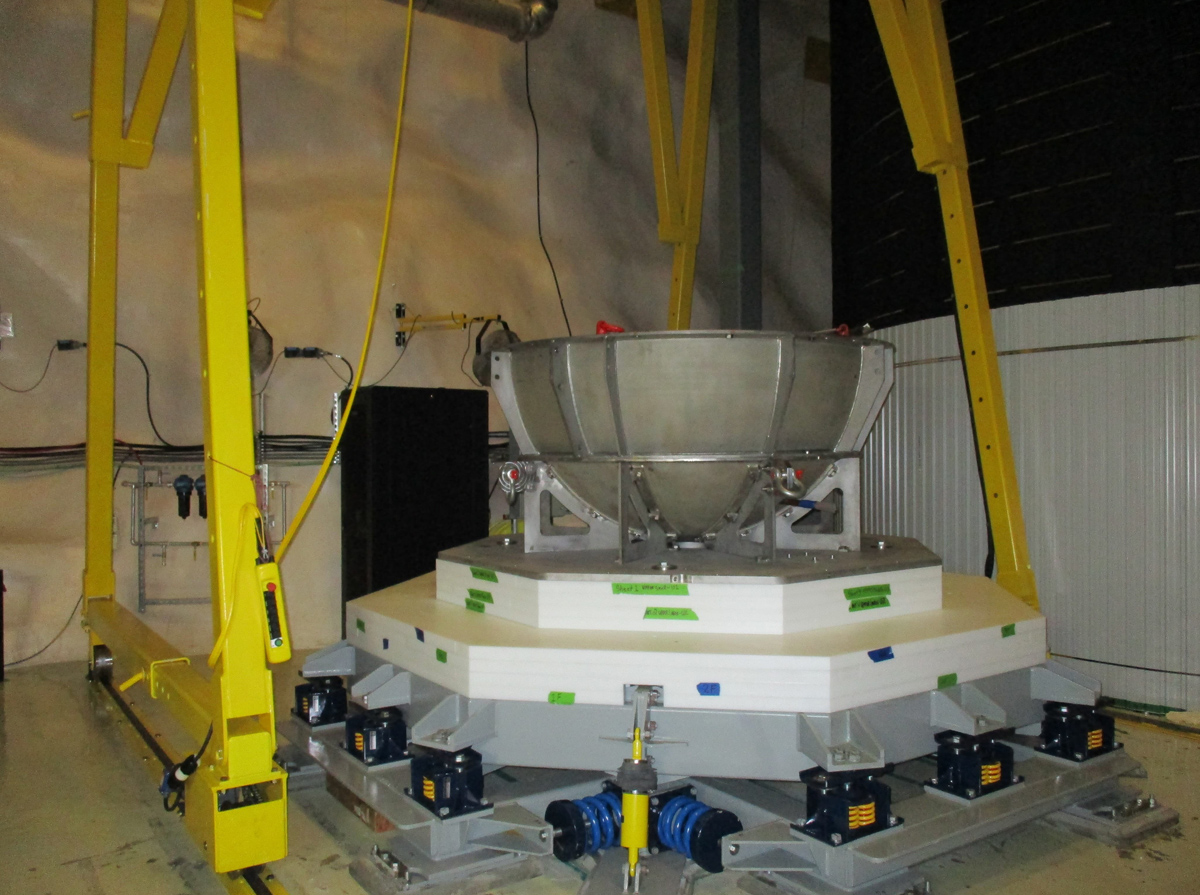

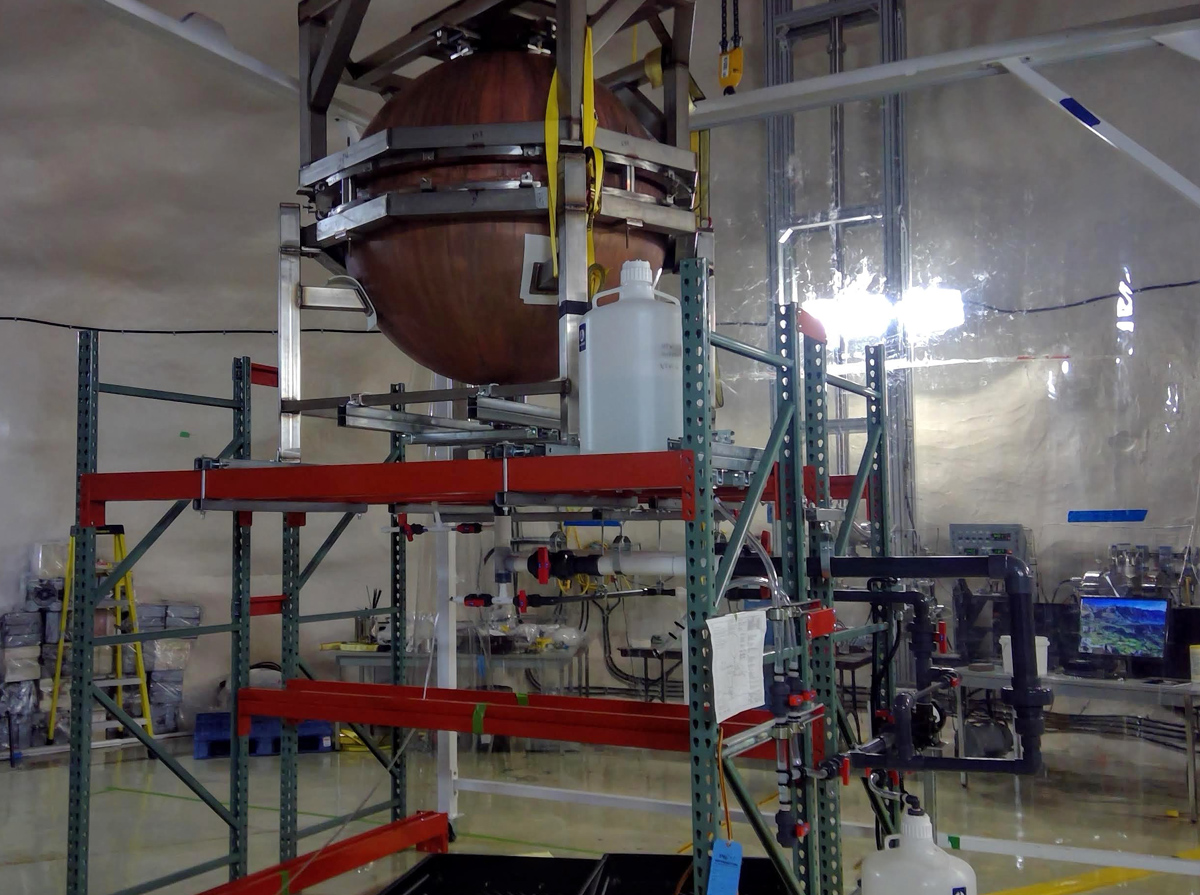

The installation of the NEWS-G detector has restarted at SNOLAB in September, after a long delay caused by the Covid-19 pandemics. It started with a final cleaning of the copper sphere, dubbed SNOGLOBE.

All the pieces and equipment had been delivered at the beginning of the year, most of them coming from France after the successful test at Laboratoire Souterrain de Modane (LSM) in 2019.

The first step of the installation was the chemical etching of the inner surface of the copper sphere. The inner surface is the only material which is directly exposed to the detecting medium: the gas. It is therefore crucial that it is free of any radioactive impurities, which would create a disrupting background to the detection of the faint dark matter signal.

In 2018, 500µm of extremely pure copper was deposited on the sphere surface through electroplating. After the sphere was fully assembled, the inside was cleaned by chemical etching: a solution of hydrogen peroxide and sulphuric acid is used to remove a very thin layer (a few µm) of copper, and together with it all the impurities that deposited on the surface.

The experiment at LSM in summer 2019 showed that this etching was not sufficient. A second etching was planned at SNOLAB, using the same technique, but with added precautions to reduce potential contaminations. In particular, the procedure was performed under nitrogen atmosphere, to prevent exposure to volatile contaminants present in air.

Queen's Physics Department

Queen's Physics Department