One of the top universities in Canada, Queen’s has a long history of discovery and innovation that has shaped our knowledge and helped to address some of the world’s deepest mysteries and most pressing questions, including issues of environmental protection, health care, and the development of advanced technologies. For more than 175 years, Queen’s has brought together and built synergies among leading researchers, scholars, and innovators making a real and measured impact.

The Queen's Partnerships and Innovation (QPI) team develops and facilitates partnerships with industry, governments, not-for-profit organizations, and other academic institutions to advance the research enterprise at Queen’s and the commercialization and protection of inventions, and to strengthen the regional innovation ecosystem in Kingston and Eastern Ontario.

This story demonstrates the long-lasting, social, economic, and international impact of Queen’s research and collaborations with industry.

Wearing a seatbelt has become second nature to drivers and vehicle passengers. You get in, click in your belt, often before the car is turned on. But the history of seatbelts in cars is quite young, with the legislation of wearing a seatbelt coming into effect in January 1976 in Ontario. The history of seatbelts in accessible transportation is even younger. Wheelchair users posed a significant transportation safety problem – how could the physically disabled be kept as safe and secure in public transportation vehicles as much as those in personal passenger vehicles?

Enter Professor Henk Wevers (now retired) and the Clinical Mechanics Group at Queen’s University who successfully developed a retractable, adjustable four-point securement system for wheelchairs and their passengers. Queen’s was approached in 1978 by Jack Colley, Manager of the then named Kingston Bus for the Handicapped. Mr. Colley was a quadriplegic and understood the importance of ensuring that wheelchair-using passengers in accessible buses needed support and protection in the event of an accident.

“At the time that Mr. Colley approached us at Queen’s University, the three-point system for passenger vehicles was already in use but there was a major gap for wheelchair users in accessible transportation vehicles,” says Professor Wevers. “We needed a system that would keep wheelchair users safe in the event of a collision.”

In addition to the mechanical engineers, the original group was comprised of Dr. J. P. Durance, MD, in the Department of Rehabilitation Medicine at the Kingston General Hospital and Queen’s University, David Siu, Research Assistant and Civil Engineer, and Gerry Saunders, Technical Assistant. By 1984, the group became part of a multi-disciplinary group of engineers and medical doctors called “The Clinical Mechanics Group” which then became the Human Mobility Research Centre (HMRC), which provided shared research space and services for clinicians, orthopedic surgeons, university faculty, students, and industry. More recently the HMRC expanded its focus and mandate and is now the Centre for Health Innovation.

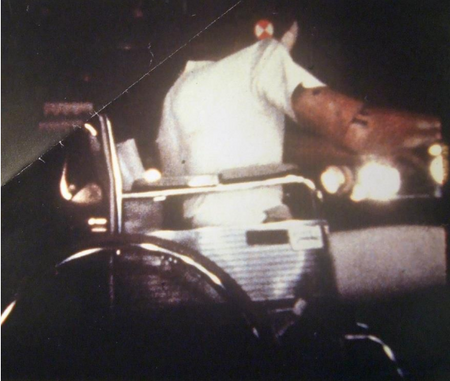

It shows the moment the van carrying the anthropomorphic

dummy crashes into a concrete barrier at 50 km/hr. The dummy

is restrained by the lap and shoulder belt and the wheelchair is

fastened to the floor of the van and stays free from the dummy

(the goal of the test).

Prior to working with the Queen’s team, Jack Colley and his team of accessible bus drivers had been using a primitive stopper system with wood blocks placed before and after the wheels of the chair. The early version also included a belt that came across the lap of the wheelchair user; however, the lap belt left the upper body without restraint, which could result in severe injury to the torso and head of the wheelchair user in the event of an accident.

With this issue in mind, the Clinical Mechanics Group got to work and by April 1980, they had developed a promising design that could address the issue. Using this newly developed design, the group applied for a $12,000 grant, which was awarded by the Ministry of Transportation and Communication. The grant enabled the hiring of a student and continued static strength testing of the restraint system. The new system involved a retractable, adjustable four-point securement system for wheelchairs and their passengers. In the event of a collision or sudden stop, the novel system isolated the forward force of the occupant from that of the chair by directing the chair’s forces to the floor of the vehicle through a common tether.

“Once we knew we were correct in the design, we started the commercialization process,” says Henk. “We did some initial crash testing at the Ministry of Transportation in Ottawa. Our design was accepted by most transit officials for the physically disabled. In fact, the drivers, and assistants of each access bus in Kingston were the first to employ the systems, and later, it was implemented by transit authorities in Toronto and other larger cities.”

By 1983, a company based on the Queen’s-developed technology was formed – Q’Straint Systems Inc. Around this time, Queen’s University was in the process of forming a Technology Transfer Office that would establish contacts with industry and businesses to license inventions and new ideas, and to provide revenue for the university.

The timing was serendipitous.

In 1984 Jean-Marc Girardin contacted the Queen’s team. Jean-Marc was from a family that owned a large school-bus company in Quebec. He saw and understood the opportunity to provide safe accessible transportation with the Q’Straint technology. Through the Queen’s Technology Transfer Office, Jean-Marc started a dialogue aimed at the commercialization of the technology. The first commercial Q’Straint system was installed into his custom-made vehicles for physically disabled persons and their families. Jean-Marc’s company of the same name as the system was set up in Cambridge, Ontario.

and adults in their own customized or standard wheelchairs.

The system provides safe securement for the wheelchair

through the four point attachment to the anchor points in the

floor. The passenger is secured by independent anchoring of

the shoulder and lap belt. This isolates the passenger from

the chair, each being kept secured during impact without

dangerous interaction between chair and passenger.

With assistance from Dr. Lawrence Schneider at the University of Michigan in the mid-80s, Jean-Marc started to commission crash testing at the Transportation Research Institute, with access to a dynamic testing laboratory that mimicked actual crash tests, which furthered the development of the technology. In 1987, the Technology Transfer Office of Queen’s University became Parteq Innovations and a formal patent licensing agreement between Girardin and Parteq governed the relationship between the research team and Jean-Marc’s licensing of the Q’Straint technology.

And the collaboration didn’t stop there. In the 1990s, the “CAN/CSAZ605-03 (R2012) - Mobility Aid Securement and Occupant Restraint (MASOR) Systems for Motor Vehicles” became the Canadian standard to address the design and performance of aftermarket wheelchair securement and occupant restraint systems, which was heavily informed by the work of the Queen’s research team and Q’Straint. Professor Henk Wevers and Jean-Marc Girardin were members of the CSA standard writing committee. Q’Straint is still a family-owned and operated company, now based in Florida and England, with Jean-Marc’s two children continuing to provide safe transportation equipment for people with physical disabilities. Transport companies in North and South America, Europe, Great Britain, Australia, Japan, and China all depend on Q’Straint technology for keeping their wheelchair-using passengers safe.

Currently, Q’Straint has 150 employees. It has its own state of the art dynamic and static test facility, the The iQ Center located in the UK. The company has developed sophisticated products such as the QLK-150, a self-docking system that enables people in wheelchair to drive their private van.

The Q’Straint basic wheelchair and occupant restraint system developed from the Queen’s University prototype is currently selling at the rate of 150,000 and over the life of the company about three million kits have been sold.

“What began as a research project at the university evolved into a major commercial employment and established safety standards for wheelchair users,” says Jim Banting, Assistant Vice-Principal, Partnerships and Innovation, at Queen’s. “This is a great testament to how collaborative efforts with academia can bring about big changes in an industry.”