Mimicking nature’s structural complexity

The functions that sustain life rely on the way living things organize at scales ranging from proteins, to cells, to tissues, to organs. Mimicking nature’s structural complexity in artificial systems to process information or energy the way living things do is a major challenge for materials that can be made and used sustainably. But meeting this challenge means scientists need much better control over how big structures arise from smaller ones, especially at very small scales.

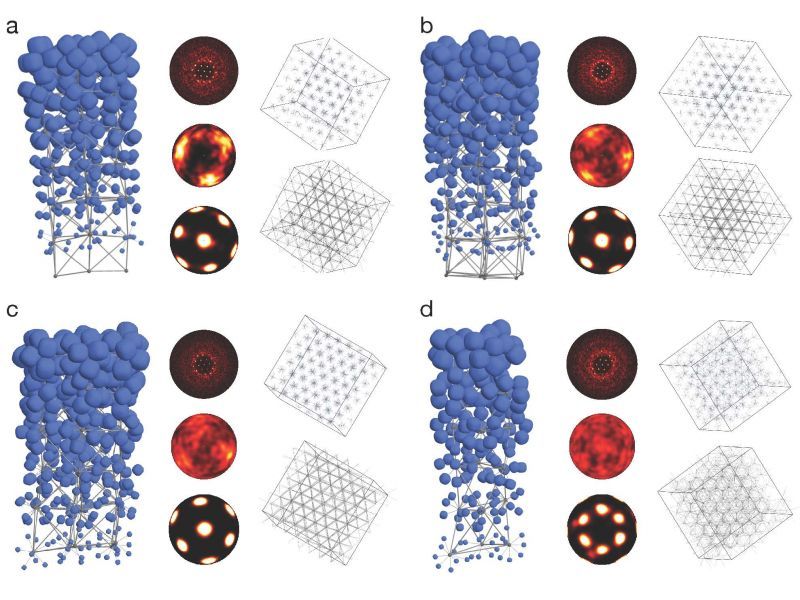

Now, a team of researchers at Queen’s University, TU Delft, and the University of Amsterdam have shown that it is possible to take nanoscale building blocks and “pre-assemble” them in different arrangements that can be used as a building material for matter with structure at larger scales.

The team’s work, which appears in Science Advances, combined high-performance computer simulation and experiments on nano-sized sand or rust particles with very particular shapes, and “pre-assemble” them into building blocks that could then assemble themselves into a larger scale structure.

“Chemists have given us very good control over structure at the molecular- and nanoscale,” says Greg van Anders, a professor of Physics, Engineering Physics, and Astronomy in the Faculty of Arts and Science, and a senior author on the paper. “And 3D printing gives us good control at tangible scales. The tricky bit is in between.”

To manage the tricky middle the team needed an approach that could reliably produce arrangements of nanoparticles with consistent structure. Laura Rossi, a professor of Chemical Engineering at TU Delft and a senior author on the paper, and Peter Schall, a professor of Physics at the University of Amsterdam, led experiments that stuck nanoparticles to water in an oil-in-water emulsion, the same kind of mixture as butter. They then heated the mixture to evaporate the water away, leaving behind clusters of nanoparticles stuck together in a set of repeatable arrangements. Importantly, the form of these arrangements depended only on the number of particles that were stuck together, not the properties of the particles themselves.

“The pre-assembly mechanism we developed here using emulsions gives us a powerful way of making consistently controlled structures right above the nanoscale,” says Dr. Rossi. “The team’s demonstration is also novel because, in contrast to many platforms for nanoscale engineering that rely on toxic heavy metals, the team’s approach uses particles that are basically smaller sand or silt grains, just with well-defined shapes.”

Simulations led by Dr. van Anders showed that over a range of scales ranging from the basic shape or interactions of the nanoscale building block, to the intermediate arrangement of pre-assembled clusters, to the larger-scale structure of materials made from pre-assembled pieces, the team could effectively switch differences on or off.

“The basic ability to pre-assemble identical pieces from different building blocks, and have them make the same structure, or to take the same building block and pre-assemble different pieces that make different structures, are really the basic ‘chess moves’ for engineering complex structures,” says Dr. van Anders.

The team is now looking forward to future work leveraging their approach for applications in pigment-free paints, hydrogen production and lightweight materials.

“As someone who works on engineering new materials, any time I’m out for a hike with my family it is humbling to see the kinds of materials that have evolved in nature and realize how far we have to go,” says Dr. van Anders. “But we believe this work takes a step toward developing materials that we hope will realize organization that leverages what we can do at the nanoscale in ways that are less damaging to the environment.”

The research was recently published in Science Advances.